If reports are to be believed, perhaps 20 million digesters— almost all of them underground masonry digesters— have been built in China, and many millions have been built in India and other countries as well. Depending primarily on the size of the digester and local prices for bricks (etc.), such a unit may cost from US$350 to US$500 and up, which is a great deal of money for a village family in most of the world. Consider that in the year 2000…

“…about 59 percent of the Indian population (495 million people) had an annual household income of less than [$280]”

World Resources Institute, “Resource consumption patterns and implications: India”, 2006

Therefore the great majority of these millions of digesters have been built with government and international NGO subsidies (is that “sustainable”?), and will have been provided to people who are already in their country’s middle class, in effect. (Families with more than one cow, for example.) All of this is fine, but it points to the fact that these digesters are not being used to ameliorate the worst impacts of poverty, which they could well do in other circumstances. There is a copious literature showing that biogas can be a powerful catalyst against poverty.

Speaking generally, virtually all of these digesters are either “fixed dome” or “floating dome” (also known by some as “Chinese-style” and "“Indian-style” digesters, respectively), such as these two:

| Two primary styles of underground digesters | ||

|---|---|---|

|

|

|

The process for building either type of digester (in any of their many variations) is roughly similar. One digs a large pit, and (most often using brick) builds up the main structure of the digester. Finishing touches are put on and in, and the digester is covered over with earth.

[Note 03/12/13: The BSP Nepal site is back up (check link to the right, in the main text), but given the history, it may go away again at some point. Please contact us if that happens and you want some of the information from the site.

Consider a partial materials list for a typical underground masonry digester (a “fixed dome GGC 2047 model”) adapted from the Biogas Sector Partnership Nepal site. (Construction plans from late 2013 are found here. We have not used them to build a GGC 2047, but they look fairly complete and useful, and are more detailed than more widely available manuals, such as this one, which is found in many forms and many places on the web.)

The materials list provided below is not complete, and so the totals shown do not reflect the complete cost. Nevertheless, based on casual visits to a few hardware sales websites, we assume the listed materials, as of 10/2015, purchased locally (i.e. at retail in the US), would cost

- $8.25 for ~100 lb bag of cement (50 kg = 110 lbs);

- 30¢ per brick (although as compared with Nepal, the size of our bricks may be different);

- both #34 “gravel” (1-1/2" to 2" rock fragments) and sand cost $35/ton (where a m3 of small rocks, sand, or gravel is about 3,800 lbs); and

- smaller gravel costs $28/ton.

We will not show the cost of each item in the table below, but based on the above information, if you are really interested, you can find out how we got the total costs we show by making your own spreadsheet, or you can contact us and we will send you what we have. Since BSP indicates one can use either rocks or bricks, we calculated based on which was cheaper.

We do not figure or include the cost of paint (last column below), because frankly it makes no sense to me that anyone could do very much that is practical with a single liter of paint when using it on a several cubic meter underground masonry digester. After all it’s made from brick or cement, and if the top (gas storage) part of it is not coated it may well not be gas–tight. Thus, see the information below the materials list for some suggestions for waterproofing (which would probably seal against gas escaping as well) the inside of the upper part of such digesters.

| Plant Size m3 |

Cost of materials needed, (partial list) on described basis |

Cement bags |

Rock (or) Bricks | Gravel (&) Sand | Paint | ||

|---|---|---|---|---|---|---|---|

| @50 kg/bag |

m3 | bricks | # of cement bags | liters | |||

| 4 | $663 | 11-12 | 3.5 | 1,200 | 30 | 60 | 1.0 |

| 6 | $775 | 13-14 | 4.5 | 1,400 | 35 | 70 | 1.0 |

| 8 | $917 | 15-16 | 6.5 | 1,700 | 40 | 80 | 1.5 |

| 10 | $1,111 | 19-21 | 8.0 | 2,000 | 50 | 90 | 2.0 |

For more on materials with which to coat the inside of the digester, see Plasters and Coats for Biogas Digesters and Gas-holder[s], pg. 61, in GTZ’s (now GIZ) publication.

A final report is from “Biogas plants in animal husbandry”:

Some tried and proven seal coats:

- multilayer bitumen [asphalt], applied cold (hot application poses the-danger of injury by burns and smoke nuisance); solvents cause dangerous/explosive vapors. Two to four thick coats required.

- bitumen with aluminum foil: thin sheets of overlapping aluminum foil applied to the still-sticky bitumen, followed by the next coat of bitumen.

- plastics, as a rule epoxy resin or acrylic paint; very good but expensive.

[*] We assume they mean that the builder should use a torch before putting on the paraffin mix, since brick coated with paraffin is almost certain to catch on fire.- paraffin [wax], diluted with 2–5% kerosene heated to 100°C and applied to the preheated masonry. The paraffin penetrates deep into the masonry, thus providing an effective (deep) seal. Use kerosene/gas torch to heat masonry.[*]

Werner, Stöhr, & Hees, “Biogas plants in animal husbandry”, 1989 [emphasis added]

Biogas digesters (actually either above or below ground) can also be made from ferrocement. The Big Difference between a water tank and a digester is that for the latter, the entire tank should be gas-tight, instead of just having the bottom and sides be water–tight, but that may be less of a difference than it might sound. In any case, a fair to quite good resource on ferrocement tanks (for water storage, not for biogas, but hey) is Technical Presentation of Various Types of Cisterns Built in the Rural Communities of the Semiarid Region of Brazil. You may also wish to look at some of the publications on this page.

Puxin, the world’s largest biogas company (from China), makes a number of biogas-related products such as stoves, including portable concrete forms (buildable molds) to produce digesters more quickly. Patiently watch this video for essentially all the information you need to understand how these portable forms work. (Note especially the shape and use of the cleats which hold the mold plates together…)

The third edition of the Biogas/Biofertilizer Handbook has some good information on ferrocement digesters as an appendix (not the info in chapter 6). (You may wish to note that rather more than half of the text of chapter 1 in this book is directly “adapted” from TCBH. Plagiarism is the sincerest form of flattery? Sigh.)

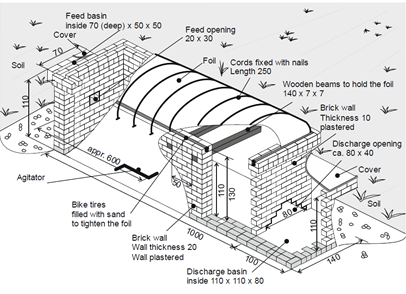

One other design should be mentioned. Recently (late June 2013), Prof. Dieter Deublein and his colleagues posted a very interesting paper on what they call the Aidewise-biogas plant. (An overview is here, and that page offers a means of downloading complete information.) The Aidewise is made primarily from bricks, and is only partially underground. The authors claim that “The Aidewise-biogas plant (ABP) is an advanced version of small-scale biogas plants…” such as those described above. The descriptive PDF has what appear to be very clear plans for making one of these things:

See much larger original image here.

In sum and as with any of these subjects, a good deal more can be said, but based on what we have seen extant on the lovely explosion–in–a–library known as the World Wide Web (do you need the acronym?), this page likely offers more resources than you will find elsewhere…

Finally, a picture from BSP, the Biogas Support Program of Nepal:

See much larger original image here.

| Next: | How to build a plastic bag digester |

| Previous: | How to build an ARTI-style digester |