Location

Patching polysty

Well, there’s no hiding from it: I screwed up. (I’m dyslexic regarding ‘right’ and ‘left’, just by the way. That’a pretty good excuse, don’t you think?)

After I cut the polysty for the panel right, it needed some mods (holes for pipes). The thing is, I put the two holes for the hot water in and out pipes on the wrong side: left, not right. Now, ordinarily, it wouldn’t matter much, because except for those two holes, the polysty is symmetrical from side to side. So all I really had to do was swap things around: put the side I had wanted to be inside on the outside and that would have been that.

But two things prevented me from taking the easy way out.

The first was that I really did not want my digester shouting at people, advertising the manufacturer of the polysty. They can advertise to the methanogens and the other bitty beasties inside the digester, as far as I’m concerned….

The other reason was that hey, if I screwed up it’s bound to happen to someone else at some point, right? And what will they do, if the screwup is bad enough that they can’t just flop the polysty around backwards and carry on? Buy another sheet of polysty, maybe?

So I’m thinking, “Wouldn’t it be better if they had some other alternatives, or at least one other alternative?” And after all, I’m the guy that’s supposed to have the answers about this digester. I think I know what might work, but will it work? Will it? How can I really, actually, factually know unless I try it?

(It may come as a surprise to you, so don’t tell anyone else: but I just make it up as I go, although based on experience and pertinent science. Then I experiment: If it works, then great. If not, then I try something else.)

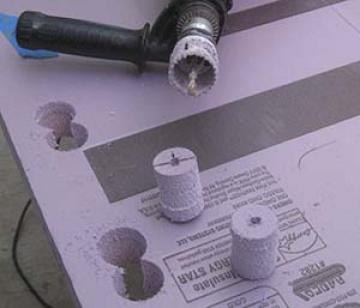

What I decided to try (risking the digester, actually, since if this does not work like I hope then, worst case, I will have to start over again and build an entirely new digester) is to put foam in the holes I should not have made and let that cure. Then make the holes that I should have made and carry on.

The first thing I did was to put tape on the side of the polsty that I wanted to show: the ⋅good side”.

Looking at the polsty from the other side, perhaps you can see how the tape has closed off the holes.

I put foam in the holes, then covered them with a plastic bag (not shown), and put some weight on top of the bag and let things sit for a while to cure. After removing the bag, this is what I found. The foam was still a little sticky inside, so I let it cure further.

On the other side, the ⋅good side”, this is what I found after removing the tape.

When things had cured enough, I took a box knife with a long blade and gave the foam a haircut (cut off what I could of the excess).

I also tried using just a long replacement box cutter blade, without the handle, and if I held it just right (I had to get my fingernail placed in the right spot), I found I could get a pretty clean shave on the foam. I don’t recommend this process, however, since if you don’t know what you are doing, you might also slice up your fingers. Please don’t.

This is what I ended up with. You will see those orange holes in other pictures of making the panel right and putting it on the digester. Now you know why they are there. Again, I don’t know whether this will work: the ad hoc foam I put in the holes has to withstand considerable water pressure; maybe it won’t. Maybe it will. We’ll see, yeah?