Location

Making the GCS (gas collection system) manifold

The Gas Collection System (GCS) is centered on four pipes that are inserted into the top of the digester, into the gas space. (That’s the top 6" of the digester, by design.) Since those pipes are held together by a bit of PVC plastic, they form “a manifold” (Merriam-Webster: “…consisting of many of one kind combined.”) We are transitioning to a wood manifold, which is far cheaper, but it will have the same length and width, and although slightly increased in thickness, pretty much everything said below still applies.

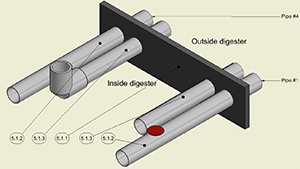

For the GCS, most of the pipes are 3/4" PVC (and in fact class 200, not schedule 40), and 3/4" PVC pipes have an outside diameter (OD) of exactly 1 1/16 inch (1.0625"). To make this manifold, then, one cuts the appropriately sized chunk from a fairly thick (3/8") plastic sheet, and then drills holes the exact size of the pipe. The parts, with SPN labels, look like this:

Four pipes and the manifold block, with labels

The pipes are marked according to how far they should stick out of the manifold, and then primer (purple in this picture) is put on the ring where the PVC pipe will be glued to the PVC manifold using… well, PVC glue.

Put glue on the pipe and the inside of the matched hole in the manifold block, then position the pipe in place.

A close-up of one of the four pipes, where it is glued into the supporting plastic for the manifold.

The SPN labels are no longer needed, and I remove them at this point because they might interfere with putting on other fittings and such, but even more importantly, they might interfere with full adhesion of the foam that will surround the pipes, and that might produce gas leaks.