A new sector:

Making a business out of biogas

(Please download a copy of the current version (here) of the installer business model spreadsheet.)

There are many ways in which [The_Cube] can be improved (and will be), but it is also true that, in it’s present state and for the first time, there is a small-scale digester available which is kittable, shippable, insulated, heatable, agitated, low-cost, and available to be manufactured by anyone with the requisite skills, anywhere.

Of course only some of those characteristics are crucial to the matter at hand, which is making a business out of small-scale biogas. Can it be done? Well frankly, I don’t know. No one knows, not for a fact. One person can design a small digester, but it takes many pairs of hands, many points of view approximating toward unity, and the time investment of at least a small group to be able to pioneer a new business sector. I need your help. The planet needs our help.…. Can we make a new business here, using this new tool? Let’s find out.

After all, previous to [The_Cube], it’s difficult to see how anyone would have been able to do the experiment. Where was the core and crucial item of equipment (an affordable, heatable small digester) necessary to even make the attempt?

Right, then. No one knows. Nevertheless, at present, what seems possible? We think that one promising area is to exploit the opportunities which appear to surround food waste.

The Food Waste Problem

The key problem which food waste poses is its strong negative impact on climate change. (Please look here for more complete information.) The primary goal is to be able to have a positive impact on this problem. And of course only businesses that survive, succeed and grow will be able to continue to have such an impact, so to obtain the greater goal, we have to be good capitalists as well. (These things are no more in opposition to one another than being idealistic and pragmatic are incompatible. The best of us are both, fervently both.)

The Food Waste Opportunity

The key point is that hidden in food waste, there is a great deal of energy, and the majority of that (more than twice as much energy as is produced as heat from a well-aerated compost pile) can be released as biogas, an excellent burnable fuel which can be used for cooking, heating & lighting. Human production of biogas requires a digester, which (as you know) is a sealed container where organic material can be kept warm, wet, and away from the air.

How much food waste is there?

In the aggregate, there is a great deal of food waste being generated. Worldwide, it appears that humanity wastes about a third of the food it produces, and the situation in the US, according to most reports, (e.g. reference ) is similar. The USDA, for example, says that in 2010 the nation threw away 133 billion pounds of its food. According to our calculations, if piled up on an area 100 feet on a side, that amount of food waste would reach 40 miles high.

But of course there is no such tower of garbage— it’s the virtual artifact of an estimate— and when we stare at the forest of a regional or national problem from 10,000 feet, the unnoticed assumption we might make is that we need a forest-sized solution; yet forests, as some have pointed out, are often made of trees.

Food waste producers: national picture

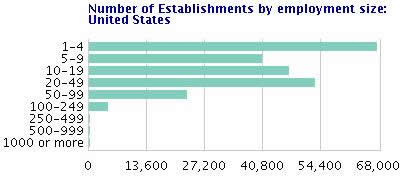

For a look at some of the ‘trees’ in this ‘forest’, take restaurants as an example. The National Restaurant Association says that 7 in 10 of all restaurants in the nation are single-unit operations. Further, the US Census reports that almost 30% of all full-service restaurants in the US have fewer than 5 employees, and nearly half (44%) have fewer than 10. Taken together, these stats imply that the majority of restaurants are both small and single-unit, which would tend to limit their options when dealing with food waste. (Whereas the owner of a large enough group of restaurants could reverse their supply chain to haul food waste to a central point and apply an aggregated solution, the small independents are unlikely to have the resources to do other than pay for someone else to deal with their garbage. Even individual franchisees of large chains such as McDonald’s may be in the same position.)

And with regard to us, and biogas, and business, the fact that so many of these food waste producers are small, means that we, as small businesses ourselves, are likely to have a good fit. We will show evidence below that many such small producers are generating amounts of food waste that— ain’t life great?— can be digested by our primary tool, [The_Cube].

On-site digestion? Never before…

As mentioned, small-scale, low-cost, on-site digestion is simply not presently possible for these small food waste producers, because suitable digester designs have never previously existed. There are a few low-cost digesters available, but (speaking as someone active in the worldwide biogas community), all known examples are too small, poorly insulated, and essentially unheated. (These might work well enough in a tropical setting, but in Europe, Australia, most of the continent of South America, most of Asia and certainly here in the US, when using such a digester at ambient temperatures digestion would halt during the winter, even in our southern-most states.)

There are, likewise, a few proprietary small digesters suited to temperate climates, but besides being available only from (and for) the company that produces them, they are so expensive that they are likely to remain poorly utilized. As well, the business strategy of the companies producing these digesters appears to have them installing and servicing customers nationally, apparently implying enormous expense to build out infrastructure in city after city. These conditions, taken together, would appear to raise the cost of such solutions to the point of market marginalization.

By contrast, our digesters are the first kittable, shippable, insulated, heatable, agitated, small-scale anaerobic digesters available, worldwide. As well, they can be produced anywhere by anyone who has the proper tools and modest skills.

Overview of business

Thus as indicated, our project is aimed at pioneering the business use of an evolving set of designs for low-cost, small-scale, temperate-climate biogas digesters which incorporate insulation and heating (because the rate of biogas digestion is temperature-dependent), and agitation (to help insure that the entire volume of the digester is in active digestion). These digesters can be locally manufactured or (eventually) purchased in kit form, and will be distributed by and serviced through a national network of independent local installers— people like you?— who will for the most part work with local small businesses that generate moderate amounts of food waste. Thus in this endeavor, there are those, primarily businesses like restaurants, who generate food waste: the producers. And there will be those, like you and I, who supply digesters and services: the installers.

So installers will deliver and set up the digesters, train the producer’s staff, and regularly service the digesters. (For the most part this ‘regular service’ would entail switching containers (IBCs? — Industrial Bulk Containers) full of effluent— the stuff the comes out of the digester— with empty containers (or alternatively, draining collected effluent, by electric pump), on a regular schedule determined by the amount of food waste produced on-site, but generally about once every two to three weeks.)

Thus installers would need to have at least one reliable pick-up truck, or a heavy duty “tray-back” pick-up, or a larger commercial truck. Whatever the case, the truck should be fitted with a crane capable of lifting two tons (about the weight of a nearly full IBC), and probably with a pump, capable of dealing with food waste effluent. (Such cranes can be purchased new for $2,500 or sometimes less, such as this one. “Macerating” pumps are widely available at reasonable prices. We expect to do more research in this area.)

For installers, having attended at least one workshop will allow them to access regularly updated business plan templates, success stories, producer questionnaires, and statistical information. (We do not have all of these at present mind you: we will be intensively developing these resources over the next two years.) As well the installers will be able to participate in a discussion forum powered by Drupal and to utilize a streamlined set of metrics and instruments for characterizing various aspects of the installer business, which we will develop and share with our installers. As mentioned in the page regarding [The_Cube], “What we do not measure, we cannot improve.” (In this context, what is true is that we must use the best tools that we can which will allow us to gain insight into and control over our businesses.)

Using these tools, we expect and hope that our installers will help us better quantify the ubiquity, size distribution and other characteristics of producers in their locality; not to generate new national estimates for some other and more generic use, but to provide insight into conditions on the ground and as experienced, and offer a growing dataset from which we can extract the correlates of successful installations and other information (eventually collected via smart phone). Individual success may flow from personal intuition, but widely shared success can only come from the kind of clarity that insightful data provides.

Stories are important too. Some stories collected from the installers will be anonymized and made publicly available as part of our shared effort to improve the catalytic impact.

Within that context of measurement, evaluation and the goal of mutually shared success, the diverse approaches the installers will no doubt apply will in effect be an evolutionary experiment toward improving the breed, and promise to illustrate, ultimately, how to achieve success in widely divergent circumstances.

Changing the percieved value of food waste

Meanwhile food waste is known to produce 8 to 12 times the biogas that farm manure does. The effluent does not suffer a loss of nutrients, and can be directly used in agriculture, (including urban agriculture) or further composted. Thus AD can provide several benefits which are superior to direct composting. The key to the possibility of establishing a business is the fact that on-site digestion results in valuable energy; no other approach does.

So food waste is really too valuable to throw away. But in a sense, that's the problem, isn't it? People throw away food waste because they don't realize how valuable it is. If they understood the value of food waste, then they would use it, not throw it away.

So: Can a small group of people with modest means change that perception, nationally and perhaps worldwide? Can we become a catalyst for change?

A parallel example of such a catalytic impact is illustrated by the biodiesel revolution, where a diverse group of early adopters was arguably the pivot of a process that changed the perceived value of used cooking oil, yellow grease. You can learn more here. The key take-home is that a similar change in value has taken place before, and it seems likely to happen again.

“The best way to predict the future is to create it”

Thus we seem to have good reasons to believe that by providing a low-cost, practical “popular” technological implementation ([The_Cube] and its progeny) and by helping produce a similar small cadre of people interested in applying this solution locally, this project can have a strong and positive impact on the perceived value (and therefore ultimately the wider utilization) of food waste. We aim to help create that reality where, in the future, it will be hard to find any food waste anywhere which is being sent to the landfill.

Can installers make a living?

The business of installers can be fairly simple, as described above, and would obviously require gaining an income more than sufficient to pay for ordinary business expenses such as rent, and including vehicles, equipment, tools and time, as well as repayment of any start-up expenses.

Along with good business practices and wise decisions, there are several key numbers which will control profitability this new endeavor:

- How much food waste can we process with [The_Cube]?

- The amount of food waste produced

- The hours-per-month required to service a producer, on average

- The local replacement value of the energy produced in the biogas as methane

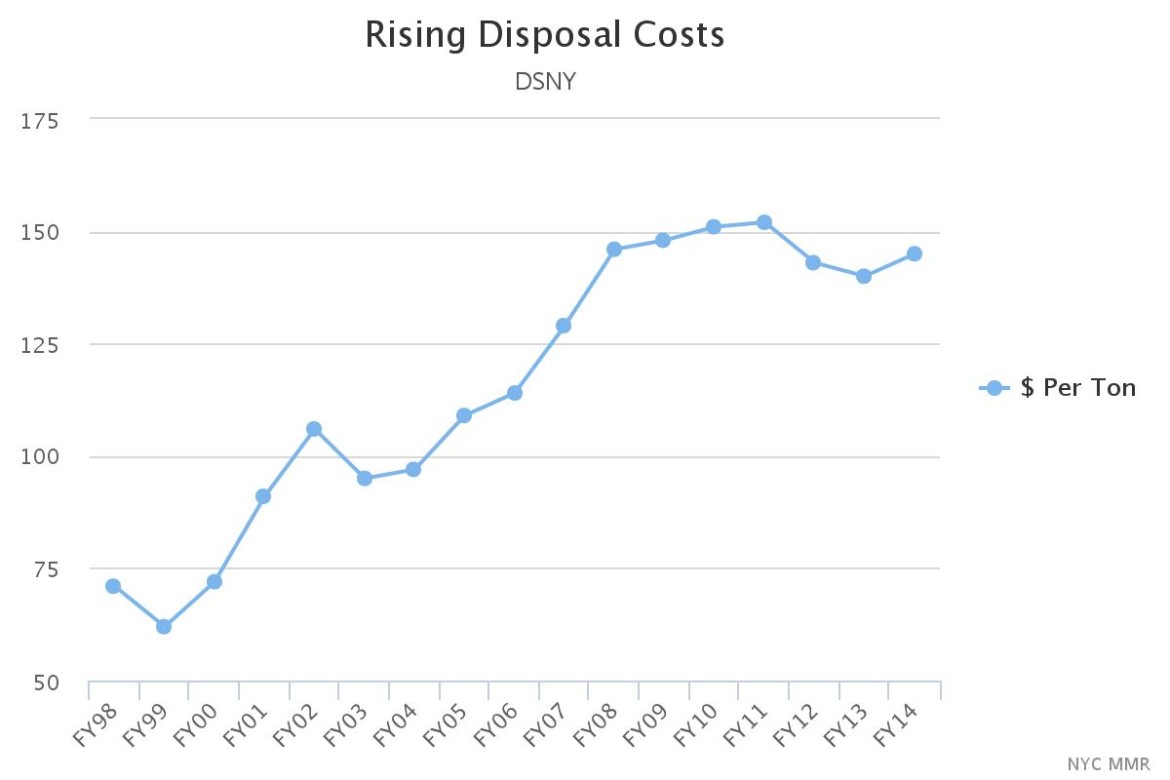

- The local cost of tipping fees (garbage collection costs)

- The installer’s monthly expenses

Several of these key numbers, in our view, and not well-enough established to allow us to state without question that this business proposal will be profitable in enough situations to make us comfortable in pushing others to try. Even where we have better information on some of the numbers, bringing them into better focus, other numbers will vary dramatically from locality to locality, meaning that the margin available for success likely varies locally as well.

I would say that there is ‘hobby’ biogas and there is practical biogas. Hobbies are good, and they do not need any better economic rationale than: Hey: it feels good. How many people ask that a casual round of golf on the weekend should turn a profit?

On the other hand, if one wants to demonstrate that something is practical, or to make a business of it (as for example as in owning a store that caters to golfers by selling clubs and balls and golf widgets— whatever they are), then the numbers are crucial. How can that person wanting a golf store go to the bank and try to get a loan unless they have some evidence— some numbers— which indicate they can make money and pay back the loan?

So, to me, this is the first critical difference between biogas as a hobby and biogas undertaken as a business: those interested in succeeding in the business are deeply interested in getting the numbers.

That, therefore, is the first order of business: To get better numbers. You can help, and we will be talking more about that in the workshop.

Meanwhile, to give you a better idea of how that list of numbers we just mentioned above might relate to profitability, we are providing an early draft of what may eventually become a model of the installer business. It's not yet, but still, what we have may be useful to you.

Therefore please download a copy of the current version of our installer businsess model spreadsheet (here).

Once again, a note of caution, however: this is a brand new spreadsheet, and it is our experience that with somewhat complex spreadsheets, when they are new they are likewise liable to have hidden errors. We will do our best to find and repair these errors, so keep checking back to see if there is a newer version of the spreadsheet.

In sum, then, as we have said from the beginning, this is an effort to pioneer this industry. We have not yet done it: no one has. But surely the time has come to use this new tool and for a few of us to begin to explore the situation locally. If you are interested in trying, please let us know, or better yet, come to the workshop and join in the fun!